20% Papermaking Dry Strength Agent

The new papermaking dry strength agent developed and produced by our company is of zwitterionic type, which can be directly adsorbed on the pulp fibers, forming ionic bonds through the combination of ions, and improving the bonding strength between fibers, thereby improving the paper’s breaking resistance and folding resistance. , Ring compression strength, tensile strength, peel strength and other physical indicators.

The effect is especially obvious for papermaking systems with more anionic impurities or higher electrolyte concentrations. At the same time, it helps to retain fine fibers and fillers, which can reduce fiber loss and reduce hair loss and powder loss. It can produce sufficient dry strength to allow the use of low-cost fiber raw materials or a higher proportion of secondary fibers.

The products are used in the paper making of cardboard paper, high-strength corrugated paper, packaging paper, egg tray mould, special paper, cultural paper, household paper and other papers.

Technical index:

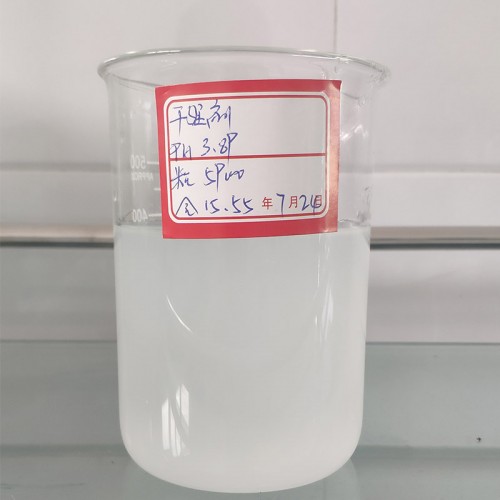

| Appearance | Colorless or light yellow viscous liquid |

| Solid content | 20±1% |

| PH value | 2-6 |

| Viscosity | 100mpa.s(25℃) |

| Ionic | Cationic |

| Solubility | soluble in water |

Main features

1. It can improve the breaking resistance, folding resistance, corrugated paper ring compressive strength, and the tensile strength and stiffness of special papers and other physical indicators.

2. Increase the retention rate of fine fibers and fillers, improve water filtration performance; improve production efficiency, reduce costs, and increase economic benefits.

3. This product is more cost-effective than Japanese dry strength agent.

Usage and precautions

1. Suggested dosage: 5-15 kg/ton of paper; dosage can also be increased or decreased according to the demand of paper type.

2. When the product is diluted, please dilute with clean water, the dilution ratio is generally 10-30 times. Slowly add this product under agitation (the product has high viscosity, do not pour it all at once), and after the dry strength agent is completely dissolved and diluted, add the remaining water.

3. The place for adding is selected where it can be fully mixed with the slurry, generally at the inlet of the sizing pump or the inlet of the pressure screen.

Packaging and storage

Packed in 50kg and 1000kg plastic drums. This product is suitable for indoor storage. Do not place it near a heat source, expose it to sunlight or freeze it.

Storage period: 6 months.